Restoring a 1909 Massey 2CWT Steam Hammer

The day you receive a new machine is always a day that feels electric. It is made all the more exciting when you have no idea what you bought…

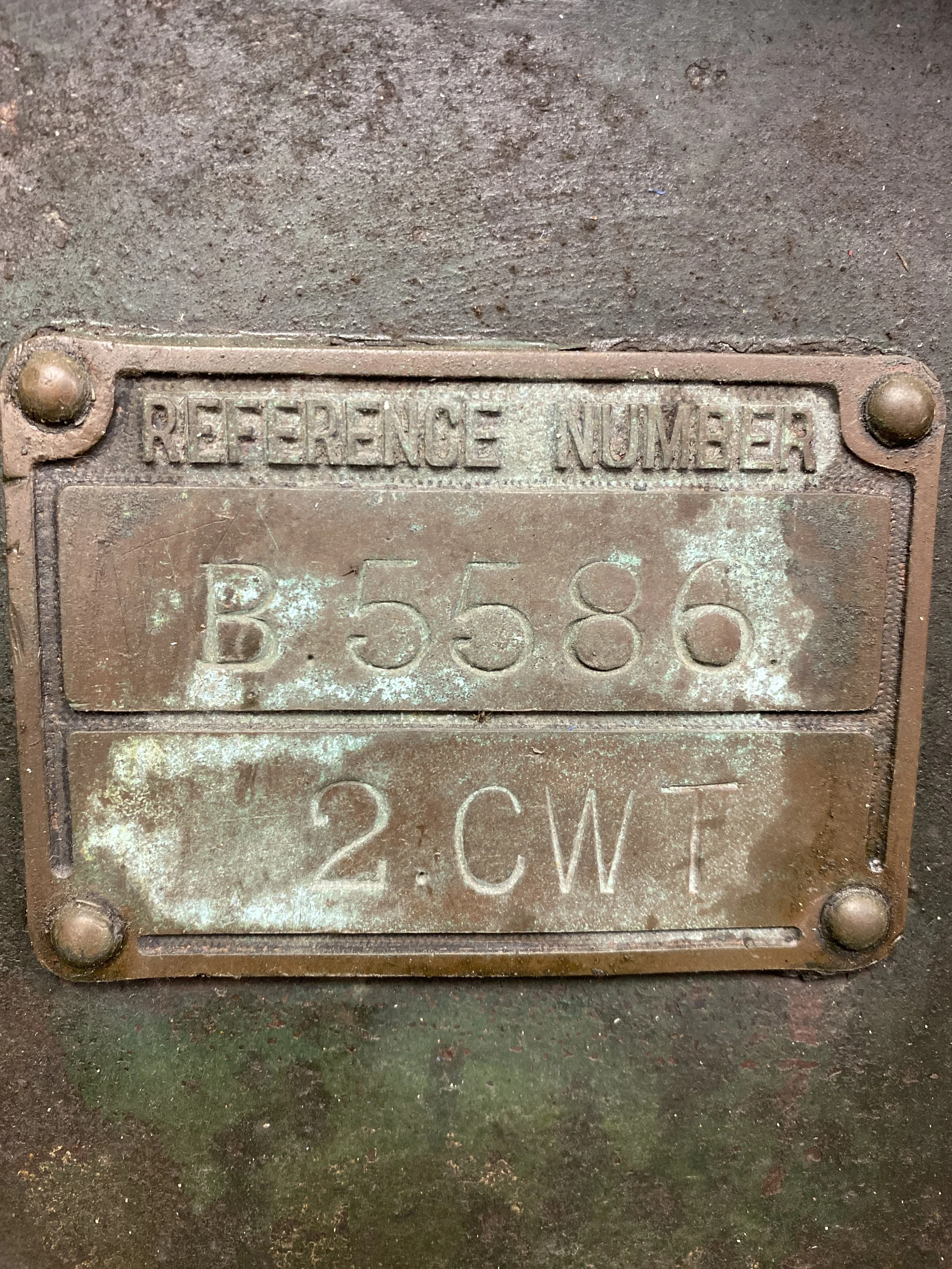

A message arrived in my Instagram from Anvil Dealer Robin Sharples last year while I was making a model Stuart Steam Hammer. He asked if I would be interested in buying a real steam hammer for a restoration project. After a few months of lining things up, it finally arrived. The machinery mover who delivered it was a man who clearly had passion for his work and industrial equipment. It wasn’t simply a case of drop the hammer and leave. He showed me countless photos and told many stores about complex moving jobs. From hoisting screw presses up from basements to making stamps walk down stair steps on bars. It is always a treat to speak to someone who loves what they do. He used his crane on his truck to drop the hammer onto the pavement, then our neighbour kindly shifted it into the workshop with his forklift. Fortunately, the hammer is quite compact. It is rare that a hammer with a 2CWT ram weight is light enough you could shift it on a 2 ton forklift, let alone a pallet truck.

With it inside, I was able to look it over and see what I had acquired. Panic set in. What on earth had I just got myself into…

I decided that Step 1 with this complex problem was to be able to discuss it and think about it. To me this means I need accurate language to describe what I am looking at. So I named as many key parts as I could with painters’ tape and sharpie. Even this helped me familiarise myself with what I was looking at and begin to understand how it might work. This also provided me with an opportunity to photograph it in it’s current state so that once pulled apart I have a better shot of getting it back together.